Where quality machines meet best-in-class service

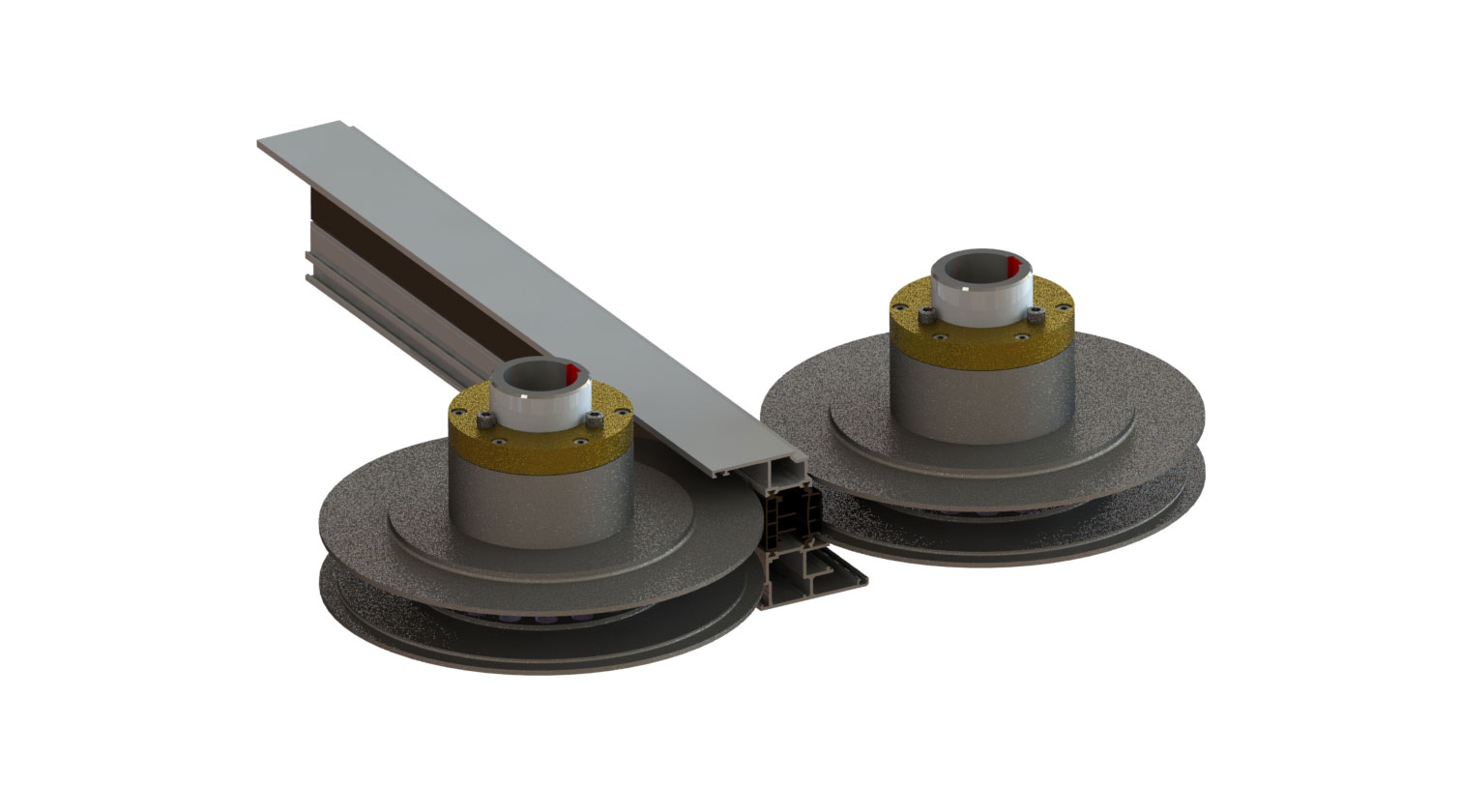

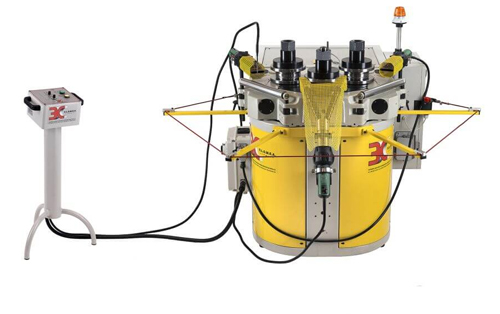

Aluminium Profile Machinery

Vinyl Window Machinery

Supplies

Featured Products

About

INT Machinery

INT Machinery Inc. is a Canadian equipment distributor that sells and services machinery, tooling and supplies for applicationts involving aluminum and PVC extrusions as well as various lightweight materials.

We employ factory trained service engineers, maintain a significant local inventory of spare parts, tools and machinery to guarantee the best service experience.

Pre-Owned Machines

Brands

INT is the home of top-quality machinery and technology from the top manufacturers in the business. Here are the brands that we carry at INT Machinery Inc.: